Source: mnn.com

Published: February 2, 2017

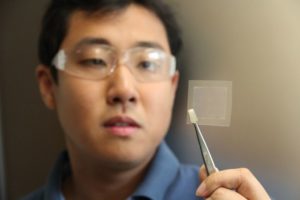

Researcher holding a graphene film made of cooking oil. (Photo: CSIRO)

Scientists in Australia have found a way to transform used cooking oil into the strongest material known to man: graphene. It’s a breakthrough that could make this wonder material cheaper than ever to produce, and thus far more applicable, reports CSIRO.

Graphene is an atomic-scale hexagonal lattice made of carbon atoms that’s so strong it’s been said it would take an elephant, balanced on a pencil, to break through a sheet of graphene the thickness of Saran Wrap. It’s roughly 200 times stronger than steel, harder than diamond, and incredibly flexible. It can even act as a superconductor under certain conditions, meaning it can carry electricity with zero resistance.

And all of this, now, from cooking oil — soybean oil, to be exact.

It all comes back to recycling

“We can now recycle waste oils that would have otherwise been discarded and transform them into something useful,” said Dr. Dong Han Seo, co-author on the study published in the journal Nature Communications.

The technique, referred to as ‘GraphAir’ technology, is surprisingly simple. It first involves heating soybean oil in a tube furnace for about 30 minutes, during which time it breaks down into its constituent carbon building blocks. This goop is then rapidly cooled on a special foil made of nickel, where it diffuses into a razor-thin film of 1-nanometer-thick graphene.

The entire process can be done in normal air conditions, which is part of what makes it such a breakthrough. Normally, graphene is produced in a vacuum at intense heat, a process that requires purified ingredients (as opposed to mucky used cooking oil). So to produce the stuff in more ordinary conditions using such a cheap, impure material — and to produce it in a relatively short amount of time — means that graphene could soon be made into a practical, cost-effective substance.

“Our unique technology is expected to reduce the cost of graphene production and improve the uptake in new applications,” said Zhao Jun Han, one of the researchers.

It also makes for a more sustainable method for recycling cooking oil that would otherwise be discarded after use.

So far, the largest graphene film researchers have been able to make with this technique is the size of a credit card, so they’ll need to learn to scale things up before it can be useful on an industrial level. That’s the next step, though, and the team is already looking for commercial partners that can help reach this goal.

This article no longer exists at the Source link above. It can be found in the Matteroftrust.org Resource Library.